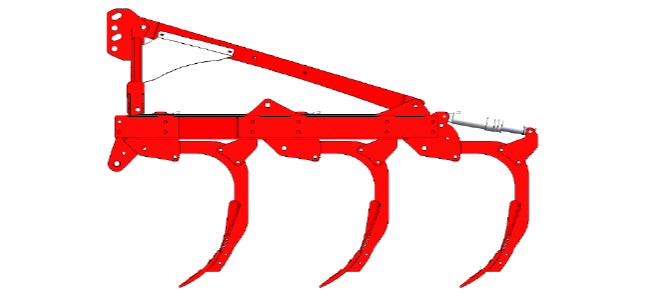

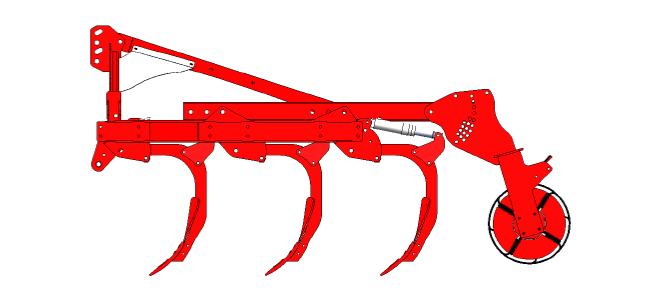

An all-purpose stubble cultivator available in 2 or 3 rows which can be used both for shallow cultivation (8-15cm) or deep decompaction up to 40cm.

With two protection systems available, shearbolt or hydraulic auto-reset, the new Versatill is Ovlac’s most versatile piece of equipment. Just one machine to carry out a wide range of diverse jobs in any soil or conditions.

MOUNTED RANGE

For medium and high HP tractors

The new Versatill is capable of working in a variety of soil types and is designed to cultivate up to 40cm deep. A choice of two or three rows of tines with 86cm under frame clearance allow a user to specify the machine to suit the work required.

The Versatill is ideal for incorporating large volumes of crop residue whilst deep cultivating to remove compaction. Alternatively, it can be used as a shallow soil cultivator for stubble cultivation and seedbed preparation.

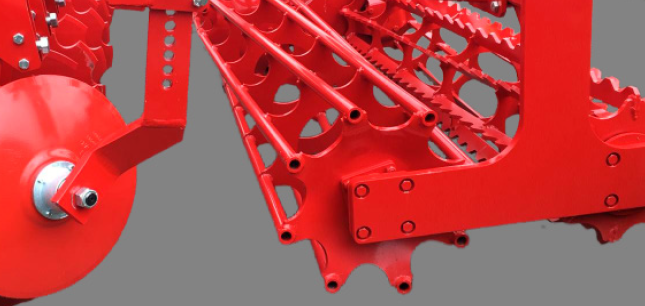

The mounted Versatill has a strong, ladder style box section frame and is designed to cope with the toughest of heavy clay or stoney conditions. Mounted versions are available in 2.4m to 6m working widths and suitable for tractors from 100hp up to 300hp.

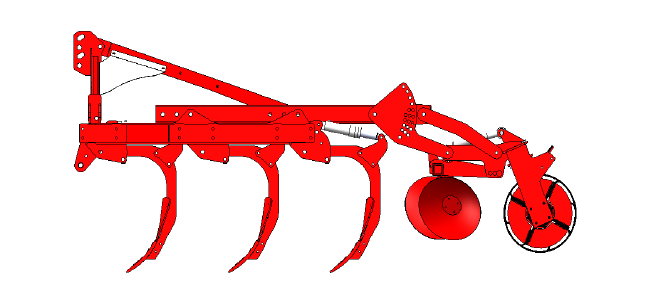

The Versatill can be fitted with rear levelling tines or discs and a variety of different roller options to crumble and consolidate the soil.

FEATURES

- 2.4m to 6m working width

- 2 rows of tines with 95cm row spacing

- 3 rows of tines with 73cm row spacing

- 86cm under frame clearance

- 30cm tine spacing

- Shearbolt or hydraulic reset (variable trip pressure)

- Various accessories and rear rollers available

Mounted Versatill cultivators are ideal for primary cultivation, the shares efficiently mix and incorporate crop residues leaving a level surface ready for final seedbed preparation.

TRAILED RANGE

For high work rates and high HP tractors

The trailed Versatill has the same main features as the mounted one. Its articulated drawbar provides weight transfer for improved traction during work and ensures simple precise depth control.

The rear axle with 3m wide track width and 500/50 tyres provides stability for transport. The axle is equipped with hydraulic suspension to reduce shocks to the frame during transport and make a comfortable ride for the driver.

Additional front depth wheels are available to precisely control the depth and prevent the tines pulling the machine in too deep.

The trailed Versatill folds to 3m transport width.

FEATURES

- 4m to 6m working width

- 2 rows of tines with 95cm row spacing

- 3 rows of tines with 73cm row spacing

- 86cm under frame clearance

- 30cm tine spacing

- Shearbolt or hydraulic reset (variable trip pressure)

- Articulated drawbar

- Front depth control wheels (option)

- Various accessories and rear rollers available

- Rear Axle with hydraulic suspension, marker boards and lights

Trailed Versatill cultivators are ideal for primary cultivation, the shares efficiently mix and incorporate crop residues leaving a level surface ready for final seedbed preparation.

FEATURES & BENEFITS

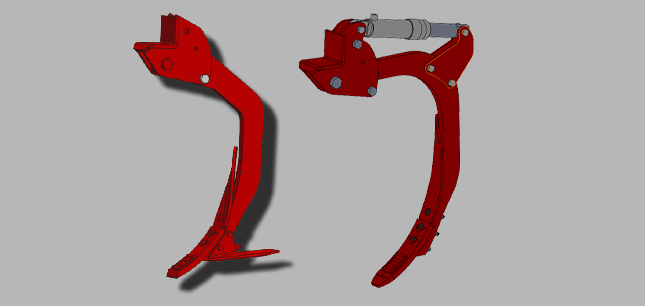

PROTECTION SYSTEMS

Shearbolt or hydraulic auto-reset

The Versatill is available with 2 safety systems: shearbolt or hydraulic auto-reset. The former is recommended for light conditions.

The shearbolt thickness, grade and position are calculated so it breaks at a pressure of 2.000kg exerted at the point.

However, the most widespread system used in Europe is hydraulic auto-reset protection with adjustable break away pressure, allowing the operator to adjust the machine to the conditions.

This system requires no maintenance and allows the trip pressure to be adjusted from the tractor cab, unlike a mechanical safety device. In fact, in stony soils, it may be preferable to work with low pressure to avoid lifting stones up to the surface. In this way excessive stress is not transferred to the frame. In heavy soil, high pressure will keep the tines at the optimum angle thus maintaining a constant working depth.

The 86cm under-beam clearance, 73cm row spacing (95 cm in 2-row versions) and 30cm tine spacing enables working in a wide range of conditions up to 40cm deep.

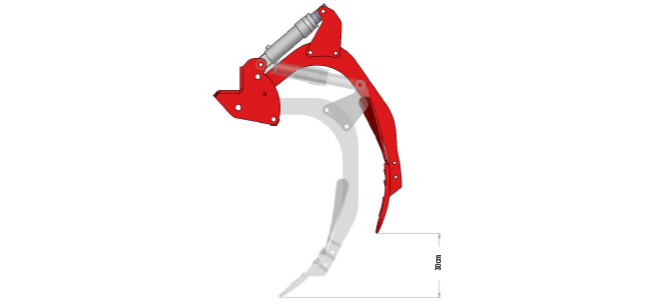

HYDRAULIC AUTO RESET SYSTEM

Advantages

The ability to vary the trip pressure depending on soil conditions allows the tines to be kept at their optimum working angle. This results in a series of advantages:

- Constant working depth and therefore correct tillage performance

- Fuel savings of up to 30%

- A significant reduction of wear as points are working at the correct angle

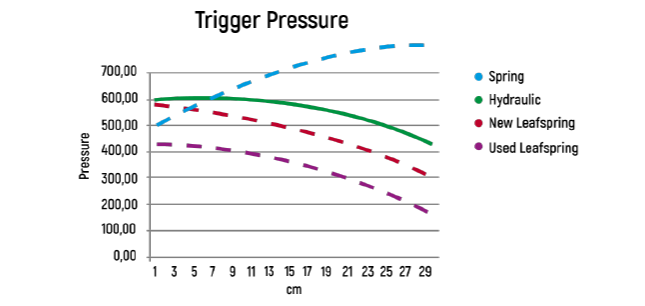

This chart shows how different security systems behave:

- The blue curve represents a traditional coil spring system. This type of break back often starts from a relatively low trip pressure which then increases rapidly as the tine trips. That means excessive stress being transferred to the chassis and main structure of the cultivator.

- The red and purple curves show the leafspring auto reset protection system. When new (red curve), the initial pressure is high, which helps keep the tine in its right position, and it decreases as the tine trips, which protects the frame and main parts of the cultivator from the stress. However, after a certain time the leafsprings get deformed and the curve moves down in parallel (purple curve). The initial breakaway force is then lower so the tine may trip too easily and may not be able to go back to its correct working position.

- The green curve shows the Ovlac hydraulic auto reset system. The initial trip pressure is set at the factory at 600kg and then decreases as the tine trips thanks to the precise geometry of the pivot points. In addition, this curve can be moved up or down in parallel as required depending on soil conditions by adjusting the hydraulic pressure accordingly. Importantly the trigger pressure does not degrade over time.

38 COMBINATIONS

The Versatill is designed to be configured to suit the task in hand. Mounted and trailed versions with two and three rows of tines can be used as a bare machine or fitted with levelling springs or discs to work in front of a variety of different types of roller.

Up to 38 different configurations allow the Versatill to be specified for primary stubble cultivation or seedbed preparation.

BARE MACHINE (2 or 3 rows)

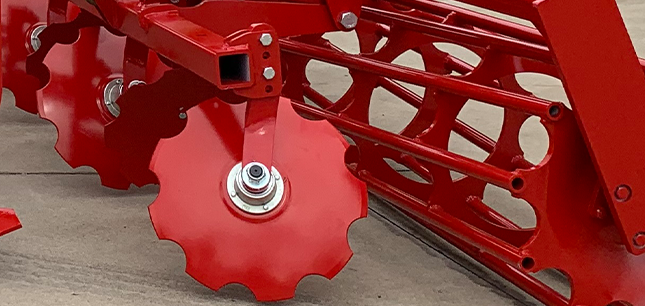

When used as a simple ripper for pan cracking or soil loosening, the Versatill can be equipped with a pair of wheels for simple and effective depth control.

MACHINE (2 or 3 rows) + ROLLER

The Versatill can be fitted with a variety of different types of roller for improved depth control, crumbling and consolidation.

MACHINE (3 rows only) + DISCS + ROLLER

For seedbed preparation the 3 row machine can be fitted with levelling discs to work in front of the roller providing an excellent, level and firm finish.

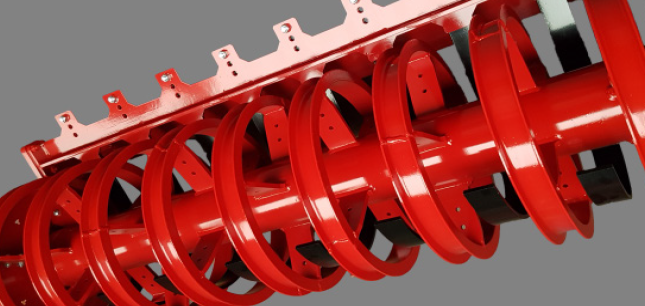

REAR ROLLERS

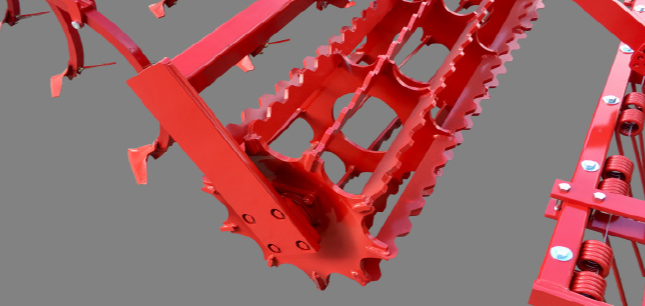

400 or 520mm notched-plate roller (80/90kg/m)

This aggressive roller levels the soil without compacting it. Ideal in dry conditions, it perfectly crumbles and breaks up clods and shreds trash on the surface.

Not recommended in wet and sticky conditions.

480 or 540mm Crumbler roller (80/90kg/m)

Ideal for cultivation on light or pre-worked soils, it consolidates without compacting the soil. Works in dry or wet conditions. The simplest and most versatile roller.

Tandem roller: 480mm Crumbler roller + 400mm notched plate roller (150kg/m)

Provides intense crumbling, even on light or already worked soils, it offers good re-consolidation without compacting the soil. The tandem works in dry or low moisture conditions.

520mm T or U ring roller (140kg/m)

Medium weight roller, the T profile is ideal for crumbling clods and plant residues and is suitable for light clay and loamy soils. The U-profile allows for work on stickier soils as its profile fills with soil and prevents more soil to building up thanks to the soil-soil contact. Both types are supplied with adjustable scrapers as standard.

520mm leaf spring roller (130kg/m)

Ideal for crumbling clods, mixing plant residues, and medium soil reconsolidation. Suitable for all types of soil, including stony soils, thanks to its spring steel rings. Supplied with adjustable scrapers as standard.

600mm V-profile roller (290kg/m)

Optimal consolidation and crumbling capacity. Suited to medium and heavy soils. Supplied with scrapers as standard.

TRANSPORT AND DEPTH WHEELS

Precise depth control is important for any soil cultivator, especially when working shallow. A variety of side and front depth wheel options are available for the Versatill to ensure the ideal specification can be provided for the specific working requirements of each machine.

6.00x9’’ 10 PR

Side wheels (option): Ideal for tillage combined with a roller on 2.50 to 3.50m machine. The tyre design stays clean in wet conditions.

200/60 14.5” 10 PR

Front wheels (option): Ideal for mounted folding models. Very easy to adjust.

200/60 14.5’’

Front twin wheels (option): Recommended for depth control and support on wider machines. The wheels are on both sides of the support arm to prevent side forces, important when working on slopes.

500/50 17”

Wheels are standard on the road transport axle of the trailed Versatill. They are fitted at the rear and are only used during transport, except in special conditions where its possible to use them to help with depth control.

POINTS AND SHARES

The Versatill is an all-purpose stubble cultivator suitable for primary or secondary cultivation.

A number of different points and shares can be fitted to Versatill legs to suit the soil and conditions.

As standard the machine is equipped with a two hole, forged point fitted with tungsten carbide wearing tiles. The design of the point ensures the optimum working angle is maintained throughout its life. The following additional point and wing options are available.

Forged point 295 x 80 x 22mm

Recommended for less wearing soils, its V-shaped stripes fill up with soil reducing wear thanks to the soil-to-soil contact.

Forged point 255 x 80 x 22mm

Heavy-duty forged point with carbide tiles. The shape of the point is kept throughout the entire lifespan guaranteeing penetration and constant working depth as well as providing important fuel savings.

(Standard in the UK)

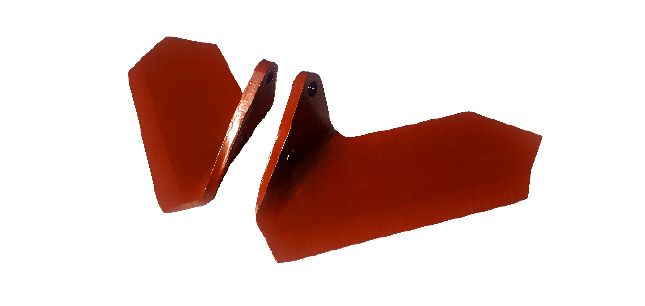

10mm right/left wings

Recommended for shallow cultivation up to 15cm deep, these wings offer a 37cm cutting width. With a 30cm tine spacing they ensure overlap across the full working width. They are also available with tungsten carbide tiles as an option.

8mm twisted guide boards

The twisted guideboards break up and turn the soil creating a perfect mix with crop residue across the full working depth. The outer tines are equipped with a specifically designed board to keep soil throw within the implement working width.

8mm tip extension

A low disturbance guide board is advised for breaking up the plough pan or carrying out soil loosening work when no mixing is needed.

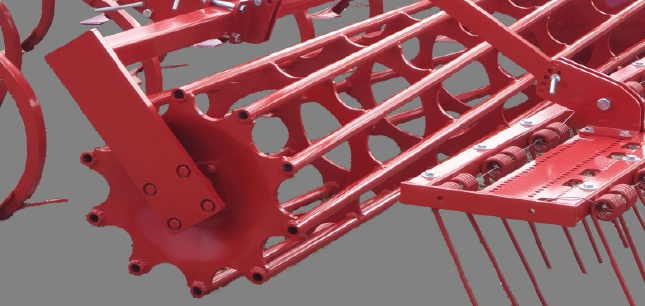

Levelling for the 3 row machine

Levelling is essential to provide an even surface for the roller to consolidate. The Versatill can be fitted with either shearbolt protected or rubber mounted discs to level the soil in front of the roller. Both options are mounted on the rear roller and their working depth is set using a central turnbuckle.

Levelling discs – Either shearbolt protected or rubber mounted discs can be specified. Both options use sealed hubs for maintenance free reliability.

The roller can therefore be used to adjust the working depth of the tines without the need to adjust the leveling tools. Similarly both levelling options are designed to ensure crop residues flow through the machine without causing blockages.

VERSATILL MODELS

Share via WhatsApp

Share via WhatsApp