The Xperience plough is Ovlac's newest flagship product and the latest innovation in reversible ploughs.

The Xperience range combines a modern new design with tried and tested features. Experience ploughs are designed for higher horsepower tractors and integrate new features which enable more versatility to cope with different soil types and conditions. The parallelogram system allows smooth and easy adjustment from the tractor cab and provides the operator with a very simple plough to set up and use.

THE RIGHT MODEL TO FIT YOUR TRACTOR

Ovlac’s range of XPerience reversible ploughs is made up of three series, each with three ranges. Therefore it is always possible to find the ideal solution to suit the available tractor HP and soil conditions.

FEATURES AND BENEFITS

PROTECTION SYSTEMS

In order to take different working conditions into account, Ovlac XPerience ploughs can be equipped with two alternative protection systems.

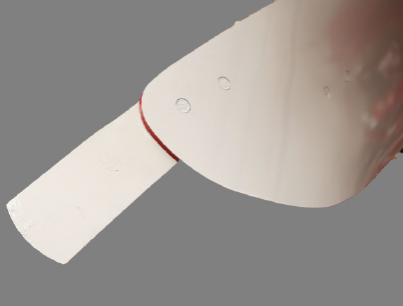

SHEARBOLT SYSTEM - XPF

The simplest of the two systems. The shearbolt thickness, steel grade and position are calculated so it breaks under a pressure of approx. 3000kg exerted at the plough point. It is imperative that broken shearbolts are replaced with genuine Ovlac bolts.

Non-genuine shearbolts with a different dimension or steel grades can result in serious damage to the plough.

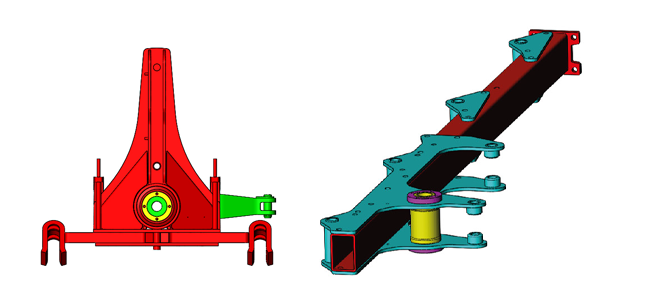

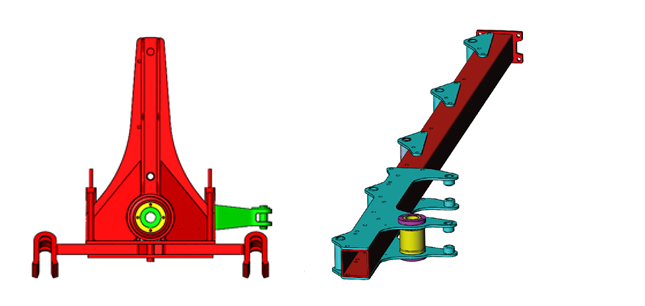

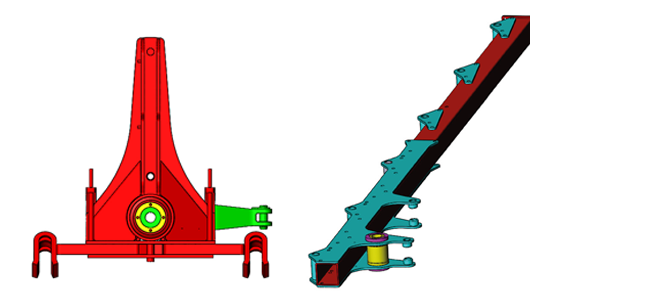

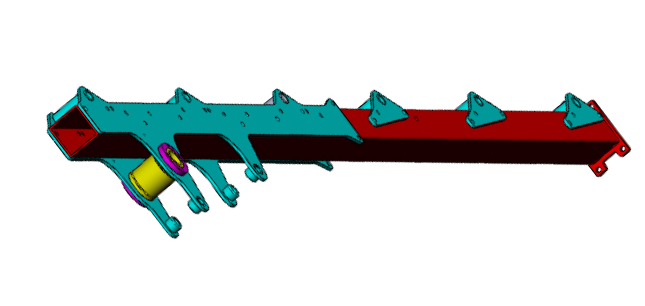

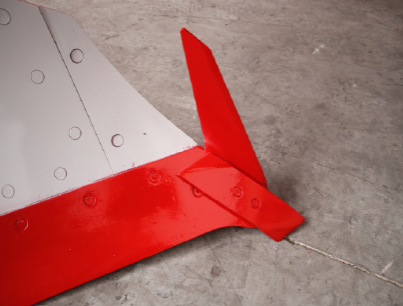

NON-STOP HYDRAULIC RESET SYSTEM - XPH

A regulated trip mechanism. This system allows adaptation of release pressure according to soil

conditions. In heavy or compacted soil, pressure can be increased in order to guarantee penetration and maintain an optimal working position of the bodies. On the contrary, in stony conditions pressure can be set lower to prevent stones being brought to the surface. In addition the legs are also attached to the beam by a shearbolt (and not welded) thus benefiting from dual

security.

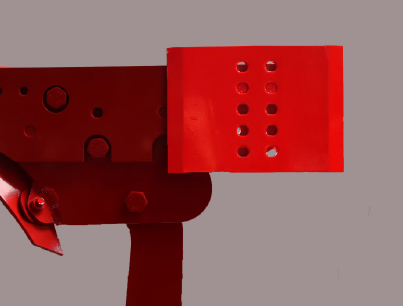

VARIABLE WORKING WIDTH

Working width adjustment is available on all Ovlac XPerience ploughs in order to adapt the plough to soil conditions or the desired work.

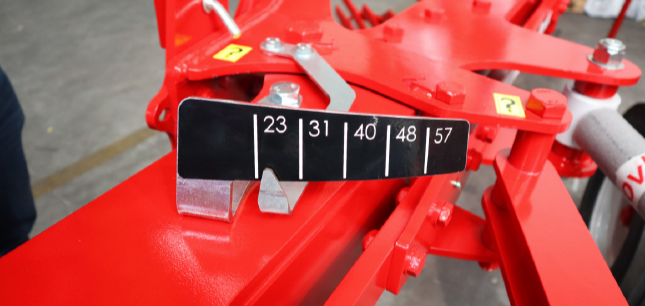

The working width of all “XP” models (XPF and XPH) can be manually adjusted by simply shifting the position of the support bolt into a different hole on the beam. There are four different working widths with 2 inch increment adjustments. 14” (35cm) to 20” (50cm).

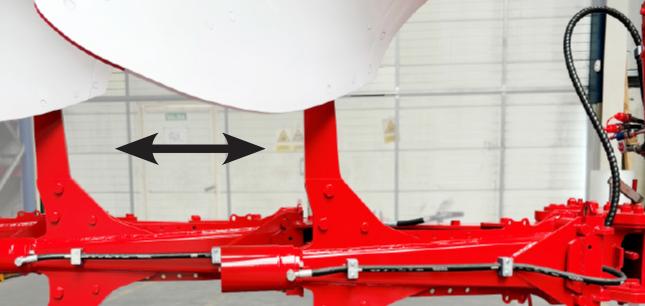

Both “XP-V” models (XPFV and XPHV) come with the well known Ovlac Varilabor variable working width as standard. This allows the working width to be hydraulically adjusted from the tractor cab between 12" (30cm) and 20" (50cm) per body (depending on the model).

This feature provides several advantages:

- Optimised output, making the most of the tractor power available.

- Adaptation to desired work including working depth, soil type, residue type and season.

- Adaptation to field variations: topography and obstructions.

Automatic Memory System: the complete range of Ovlac XPerience reversible ploughs come as standard with an automatic memory system. This closes the plough main frame to its minimum width to guarantee gentle turnover and avoid the rear end of the plough hitting the ground. Once the turnover operation is complete, the plough automatically returns to the originally set working width.

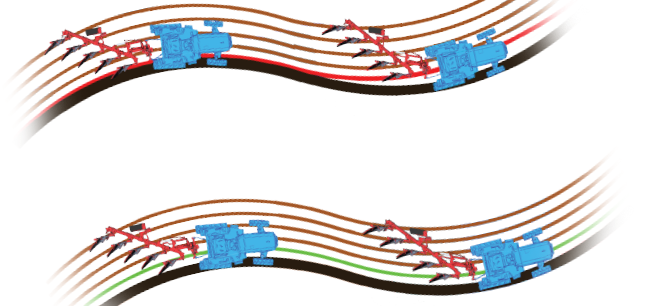

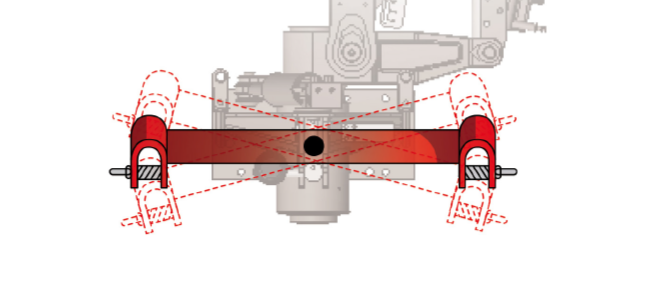

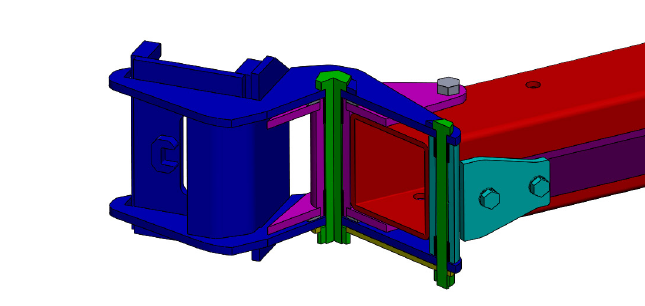

OSCILLATING CROSS SHAFT - AUTOMATIC SELF-ALIGNMENT

Ovlac XPerience ploughs are equipped with an Oscillating Cross Shaft with a centre pivot. The plough is pulled from the centre pivot point which ensures it can move independently to follow the tractor and find the perfect balance between the side pressure exerted on the mouldboard and the landslide.

Therefore once the plough is set correctly it is not necessary to make complicated adjustments in order to ensure the plough pulls straight. In work the plough will follow the tractor perfectly.

Alignment is corrected with no need for operator input. Furthermore with the Hydraulic Vari width ploughs the Oscillating Cross Shaft automatically compensates for working width adjustment. It could not be simpler.

When lifting the plough for transport or turn over, the Oscillating Cross Shaft automatically locks itself in the central position.

The cross shaft movement also makes it very easy to hitch up to the plough. In addition to the operational benefits the Oscillating Cross Shaft significantly reduces strain on the whole plough and fuel usage.

The Oscillating Cross Shaft allows the operator to plough around headlands and irregular shaped fields which increases daily output.

PARALLELOGRAM BEAM LINKAGE

Parallel beam alignment linkage combined with the Oscillating Cross Shaft mean Xperience ploughs offer true on-the-move vari width. No additional adjustment required.

LONGEVITY DESIGNED IN

On Hydraulic Vari width models (XPV), the Hardox 500 legs are bolted onto the frame. Therefore if the worst happens, and one is damaged it can easily be replaced. In addition, the leg pivot points are not part of the main frame, so the frame is not weakened or subject to any wear. The pivot points are also equipped with wear resistant casehardened bushes and greasing points to ensure a long life.

SUBSTANTIAL, SIMPLE AND RELIABLE MAIN BEAM

The main beam is made in high quality “Domex” Swedish steel and is 100% free from welding - therefore tension and weak spots are eliminated. Furthermore, at the front of the beam where the load and stress are the highest the frame is reinforced with “Hardox sandwich plates”.

NON STOP PLOUGHS FOR THE HARDEST CONDITIONS

The 3D articulated Security Rod linking the leg holder to the main frame has been designed to withstand the most rigorous conditions. It provides protection from sideways and vertical force as well as enabling break-back.

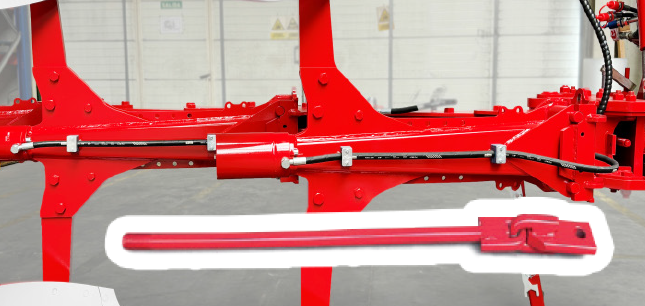

HYDRAULIC FRONT FURROW ADJUSTMENT

All Xperience ploughs are fitted with hydraulic front furrow adjustment as standard to make switching between tractors simple and to allow hillside compensation.

IMPROVED LEG CLEARANCE

The straighter leg design increases clearance between furrows to allow more trash and soil through without blockages. Ovlac 95cm ploughs have more clearance than other ploughs with 100cm spacing.

DEPTH WHEELS

A large range to meet your needs

Ovlac XPerience reversible ploughs can be equipped with a number of different wheel types.

There are Depth Control Wheels or Combi Wheels, for depth control and transport.

In terms of position Ovlac provide either Rear or Advanced Wheels.

Rear Wheels ensure optimal plough balance as well as better weight transfer to the tractor whilst ploughing.

Advanced Wheels are advisable when trying to get closer to field boundaries and obstacles, they also result in less strain on tractor arms when in transport and during turn over as the centre of the gravity is closer to the tractor.

Rear depth control wheel 280/70

Rear depth and transport combi wheel 340/55

Advanced depth and

transport combi wheel 340/55

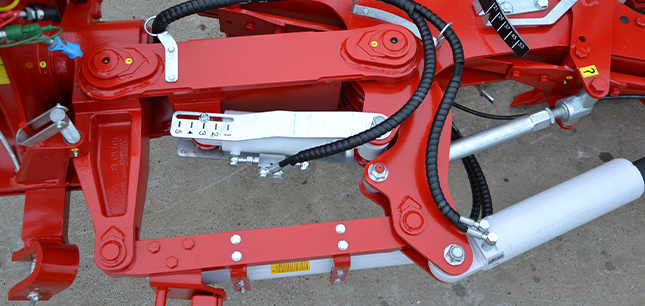

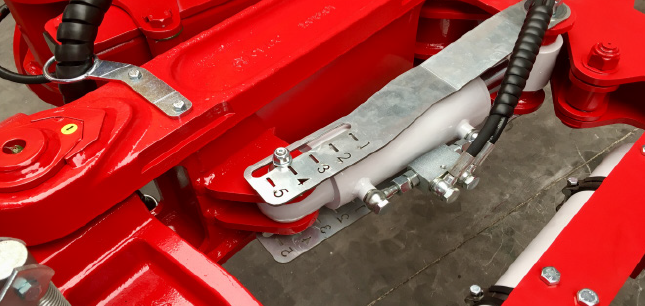

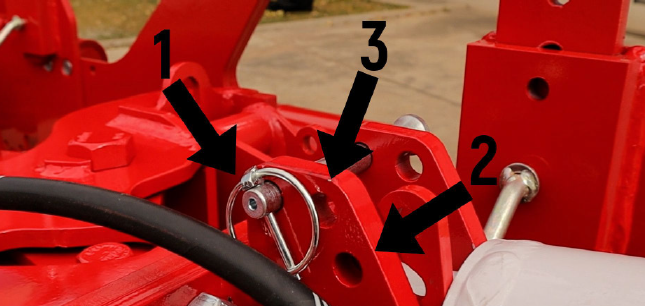

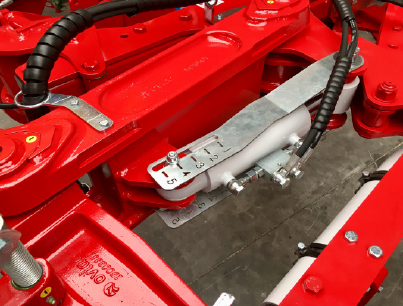

3M IVERSET SYSTEM

Unique hydraulic Rear depth control wheel 280/70 utilising 3M Iverset System.

Quick no-tools depth adjustment.

Clips are easily added and removed to adjust the depth.

Mode 1

In Mode 1 Ovlac’s hydraulic rear depth wheel allows a gradual start and finish on the headland. This means shorter “in’s and out’s” on the headland and therefore less passes to finish the field.

Mode 2

Set in Mode 2 the hydraulic rear depth wheel controls depth at the edge of the field so operators can plough right up to the field boundary.

(Mode 2 setting not available for combi wheels).

Mode 3

Set the wheel in mode 3 to allow it to move freely.

XPERIENCE ON-LAND PLOUGHS

XPerience On-Land (XP-OL) is the next step in the evolution of the XP design, adapted to work both in-the-furrow or on-land. This is the result of several years of research, since the launch of the first XP, as well as incorporation of Ovlac’s expertise in the design of soil working equipment.

The most significant change on the XP-OL model is an oversized paralellogram with two cylinders. The first of these cylinders controls the width of the first body (in-the-furrow or on-land), as well as closing in the plough for gentle, trouble-free turn over. The second cylinder controls the working width.

Changing position from in-furrow to on-land is as simple as opening or closing a valve, with no need for any tools.

Working on-land is necessary with large tractors, dual wheels or wide tyres. Thus the XP-OL is designed to work with

tractors up to 3.2m wide.

Another very important point to consider is the ability to work with GPS auto-steering systems.

Agronomically, working on-land has a series of advantages, such as less compaction at the bottom of the furrow,

and improving traction which reduces potential further field operations.

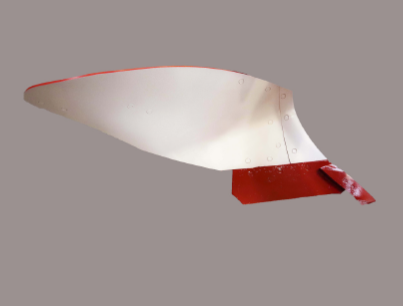

BODIES

Range of five plough bodies

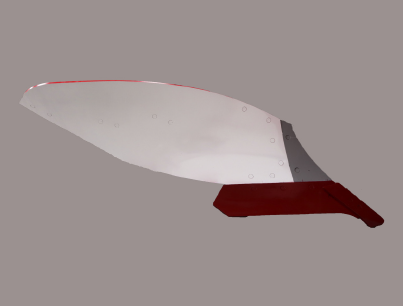

Ovlac offers five different plough bodies which enable the most suitable option for a specific ploughing technique and soil type to be selected. All genuine Ovlac mouldboards (with the exception of the slatted and plastic boards) are 8mm thick and undergo a unique case-hardening process in order to achieve over 62 HRC on the surface while still offering a soft core to prevent breakage.

In addition to guaranteeing a long wearing life for the mouldboard the smooth surface produced by the case-hardening process improves soil flow and reduces sticking.

V-90 (common for UK conditions)

Leaves a wide furrow; recommended for very wide tractor tyres (760 mm). Very good soil inversion thanks to its extra length. Similar power requirement to body V-97. For working depths between 12 and 30cm.

V-97

All-purpose body for all soil types. Designed for very low tractor power. Working depth between 15 and 30cm.

V-34 (supplied as standard)

All-purpose body for all soil types. Soil inversion with limited tractor power requirement. For depths between 15 and 35cm.

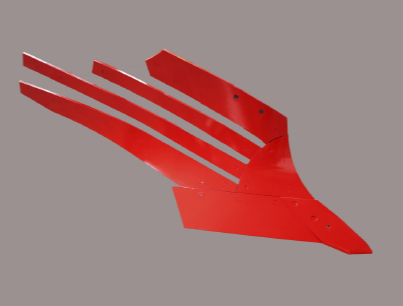

V-LOV

Slatted mouldboard. Suitable for sticky soils. All wearing parts mounted with conical bolts to lengthen the slat and bolt lifespan.

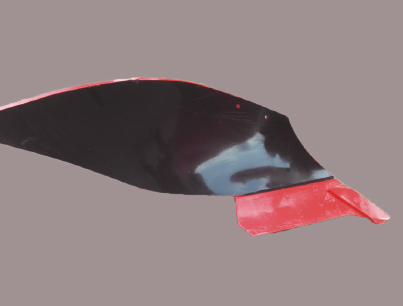

V-PLAST

Plastic mouldboard. Recommended for very sticky soils with no stones. Same geometry as V-34 body.

8mm thick mouldboards - longer working life.

Case-hardening increases surface hardness, (more

than 62 HRC) for a longer working life while keeping

a soft, flexible core.

XPERIENCE PLOUGH MODELS

OPTIONS AND ACCESSORIES

A wide range of accessories are available in order to adapt the plough to all soil types and working conditions.

Trashboard

Grass Skimmer (G)

High Capacity Skimmer (HC)

Two skim mouldboards are available: Universal and High Capacity. It is important that Skimmers are set to the correct height. In order to make this simple a no-tool adjustment system is standard on all Ovlac plough skimmers.

Spring reset protected smooth or scalloped disc coulters

Smooth or scalloped disc coulters

Tailpress

Knife Coulter

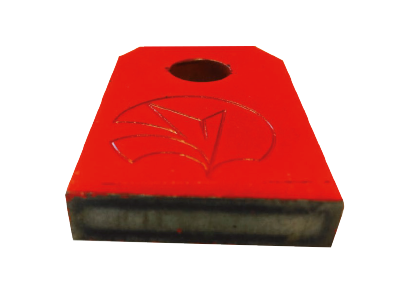

Additional landslide wear plate

Reduces main landslide wear and therefore running costs

Memory cylinder.

(Standard on all Xperience ploughs in the UK)

Hydraulic shock absorbers

For smooth operation on headland. (Optional on in-furrow models, standard on On-land ploughs)

Hydraulic front furrow width adjustment.

Share via WhatsApp

Share via WhatsApp